It seems like it wasn’t long ago that the average person paid little to no attention to logistics, let alone the function of the supply chain. Physical and digital stores simply had the goods they wanted to purchase; money was exchanged for goods, and life went on its merry way.

Fast-forward to a world riddled with lockdowns and shutdowns due to a global pandemic, where every consumer felt the pain of slow and congested supply chains. The average customer experience ranged from frustration to desperation as scarcity, outages, and delivery delays became commonplace. Suddenly, the supply chain was a hot topic for everyone, not just logistics and procurement officers.

With the pandemic behind us, the importance of the supply chain hasn’t been lost on consumers — quite the opposite, really. Now, the supply chain, and more importantly, supply chain efficiency, has become the cornerstone of customer experience. Not without reason — as a business, improving supply chain efficiency is almost directly tied to minimizing costs and maximizing output, helping deliver high-quality products to customers on time.

Businesses continuously seek ways to improve supply chain efficiency through various strategies and technologies. While this article will explore its impact on customer satisfaction, we begin by discussing the different supply chain performance metrics used to measure supply chain efficiency.

Key Performance Indicators (KPIs) to Measure Supply Chain Efficiency

Supply chain efficiency refers to the ability of the manufacturer or retailer to move and deliver goods to the customers as effectively as possible. But doing that means leveraging the correct KPI to measure these efficiencies. Here are some of them:

1. Order Fulfillment Rate

This KPI measures the percentage of orders fulfilled on time and in full. A high order fulfillment rate indicates a reliable supply chain that consistently meets customer expectations.

2. Inventory Turnover Ratio

This metric measures the number of times inventory is sold and replaced within a given period. A higher turnover ratio suggests efficient inventory management processes, reducing holding costs and minimizing stockouts.

3. Supply Chain Cycle Time

This KPI tracks the time it takes for a product to move through the supply chain, from raw materials to delivery. Shorter cycle times reflect a more responsive and agile supply chain capable of swiftly adapting to market changes.

4. Perfect Order Index

This comprehensive metric measures the percentage of orders delivered on time, complete, and without damage. Achieving a high perfect order index clearly indicates supply chain effectiveness and reliability.

5. Supply Chain Cost as a Percentage of Revenue

This KPI assesses the total supply chain cost as a percentage of revenue. Lower logistics costs relative to revenue indicate a more efficient supply chain, contributing to better profit margins.

6. Customer Satisfaction

Directly measuring customer satisfaction with the delivery speed, quality, and reliability of product delivery provides valuable insights into the effectiveness of the supply chain from the customer’s perspective.

7. Supply Chain Responsiveness

This metric evaluates the ability of the supply chain to respond quickly to changing customer demands. High responsiveness ensures that businesses can meet customer needs promptly, enhancing overall satisfaction.

Each metric highlights a different facet of how supply chain efficiency impacts the customer journey. Customer satisfaction is particularly powerful, as it connects operational performance directly to the customer’s perception of value. For instance, tracking how delivery reliability influences satisfaction can guide businesses in prioritizing improvements that matter most to their audience, eventually building their competitive advantage.

Meet the Customer-Centric Supply Chain

One of the biggest impacts of e-commerce on the retail scene is how it puts customers front and center. Before, retail options were decidedly more narrow, with them being limited to big-box stores and small independent shops. With few options to choose from, the customer experience was little more than hoping the store had what you were looking for and maybe a sale or two.

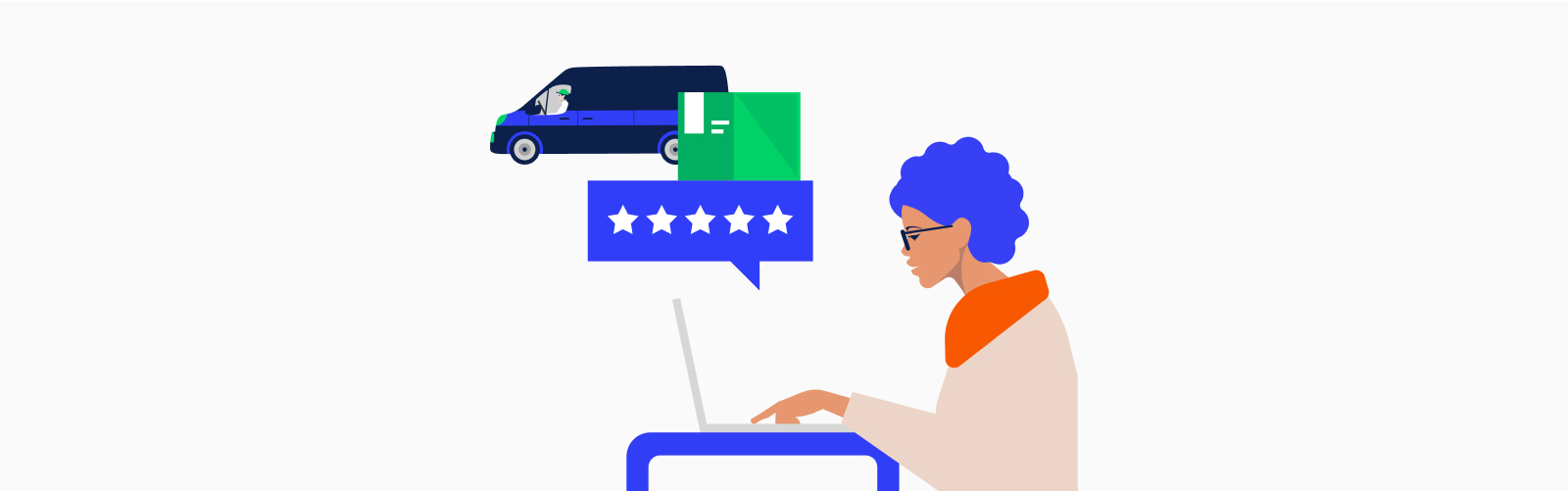

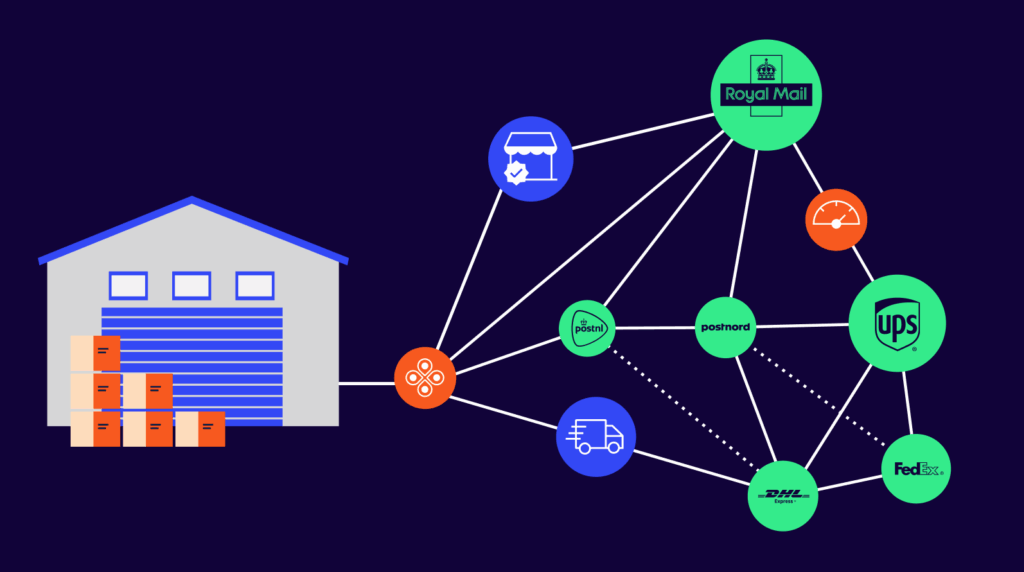

Now, however, that’s all changed, and arguably for the better. The customer-centric supply chain puts the customer front and center, because now the customer can shop around the entire world from the comfort of their own home. Supply chain software plays a crucial role in managing customer orders and improving delivery reliability. Now, instead of big-name box stores being the only game in town, there are dozens, if not hundreds, of competitors, all vying for the customer’s patronage.

So, how do companies make themselves stand out from the crowd? By focusing on the customer experience. Think of it this way — if two companies offered the same line of products at comparable prices, but only one is known for reliable delivery, which company would do better? While this is perhaps an oversimplified example, it’s sometimes the little things that make all the difference for a customer.

At this point, customer satisfaction has become inseparable from supply chain efficiency. According to a survey conducted by Gartner, 83% of surveyed supply chain leaders say that they are being asked to improve the customer experience (CX) as part of their organization’s digital business strategy.

The Growth of Customer Expectations

One of the biggest things that came from the customer-centric supply chain is the rise in customer expectations. As mentioned above, how many customer experiences began and ended with a trip to a retail outlet. While a nicety, customer service wasn’t always a priority, leading to many frustrating customer service horror stories.

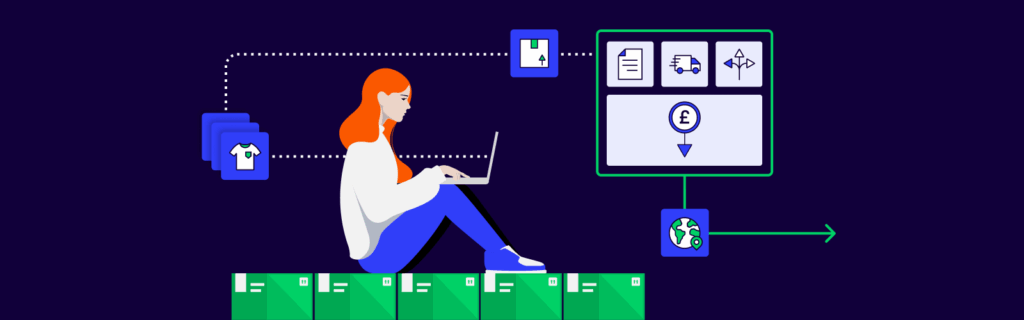

That’s all changed, however. Customer service has become the crux of retail. Customers expect prompt and courteous attention whenever and however they choose to engage with a company. Returns need to be as quick and as unintrusive as possible. Customers expect to have several different options when it comes to shipping, including the ability to prioritize delivery speed over cost and vice versa. Last-mile delivery options, including white-glove services for larger purchases, are also a bonus.

Simply put, customer expectations are based on having access to the range of delivery options and their flexibility. The inability to offer this variety of options is nearly as fateful as a reputation for poor delivery reliability. It damages a customer’s opinion of an organization, which in turn damages trust and customer relationships.

The Era of Unified Commerce

E-commerce was merely a stepping stone in the evolution of retail and the beginning of a true focus on customer satisfaction. One of the biggest retail trends in 2024 is the shift from omni-channel retail to a phase of unified commerce.

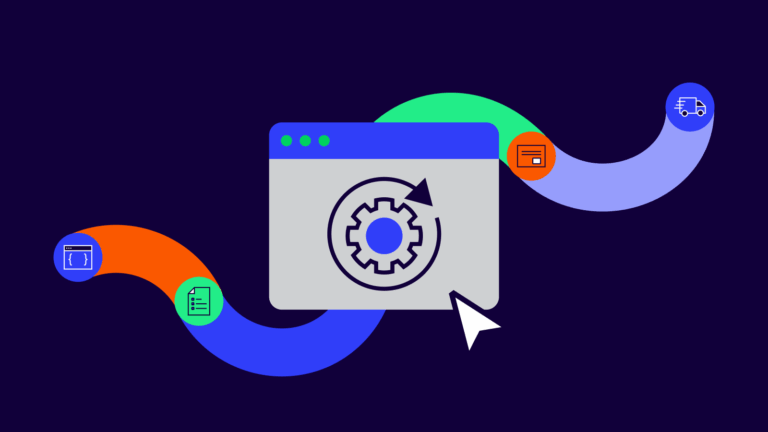

At its core, unified commerce is about bringing all customer touchpoints onto a single platform where they can browse, shop, interact, and explore products in a variety of methods, all while having a customer experience specifically tailored to each customer. The supply chain operations reference (SCOR) model provides benchmarking tools and twelve key performance metrics recommended for organizations looking to enhance their supply chain processes.

This is largely because the consumer’s buying path is no longer linear and hasn’t been for some time. According to our 2024 E-commerce Delivery Benchmark Report, 75% of shoppers use digital and physical touchpoints on the same customer journey, whereas only 15% browse and buy online exclusively. This means that brick-and-mortar stores will still play a vital role in retail, but the essence and nature of physical retail stores will be changed fundamentally.

Reliable delivery and delivery speed are two of the most important attributes of a retailer, as customers expect flexibility in their shopping experience. For example, a customer enters a clothing store and likes a particular sweater. In a world of unified commerce, the customer would be able to scan the tag on the sweater using their phone and see the full range of sizes and colors available, pick and choose which ones they want, and have them delivered to their house, all while standing in the physical retail store. That level of service will define the customer experience and loyalty.

Supply Chain Optimization is All About the Customer Satisfaction

In the past, when we were to measure supply chain efficiency, it was all about managing inventory and ensuring deliveries were made to retailers on time to keep shelves stocked with saleable products. While these are still incredibly important aspects of a healthy and well-functioning supply chain, they are no longer the sole purpose.

Instead, the modern supply chain drives the customer experience and takes shopping to an entirely different level. Supply chain performance can be measured and enhanced through various metrics and practices, focusing on responsiveness, efficiency, and cost management. Delivery speed to the customer’s front door is just as important as the delivery to the retail outlet that needs to stock their shelves.

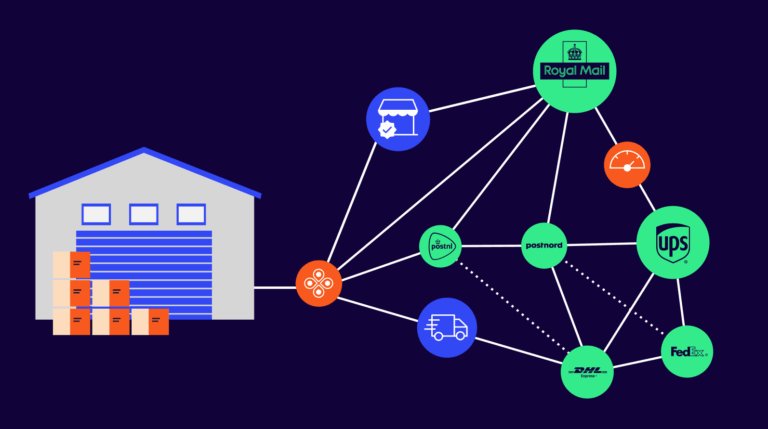

Retailers and organizations will need to learn how to walk the line between a seamless customer experience and becoming the supply chain efficiency model. As retail continues evolving from omnichannel shopping to unified commerce, supply chains will become incredibly diverse, intricate, and interwoven.

So what can retailers do to start preparing for this paradigm shift? Now, more than ever, it’s important to begin taking steps to optimize and automate supply chain processes, making it both resilient to disruption and flexible to handle the coming changes.

Want to learn more about these changes and other key consumer trends? Click here to download our 2024 Ecommerce Delivery Benchmark Report.

Want to learn more about how Metapack can help your company elevate the customer experience? Click here to learn more and schedule a demo today.