There was a time, in living memory, when the only way to purchase anything was to go to the store, at the very least. While mail-order catalogs and call lines were certainly in circulation, ordering items via mail or phoning an order in was an incredibly time-consuming process. In short, it was easier to go to the store. The nature of retail has changed drastically since then. Omnichannel retail, a retail strategy that provides customers with multiple ways to shop or interact with brands, has become the norm.

In practice, customers now interact with a brand through multiple touch points, both digital and physical. According to a recent survey, 91% of respondents said they prefer brands that offer omnichannel experiences. A Metapack study found that 75% of shoppers use both digital and physical touchpoints on the same customer journey.

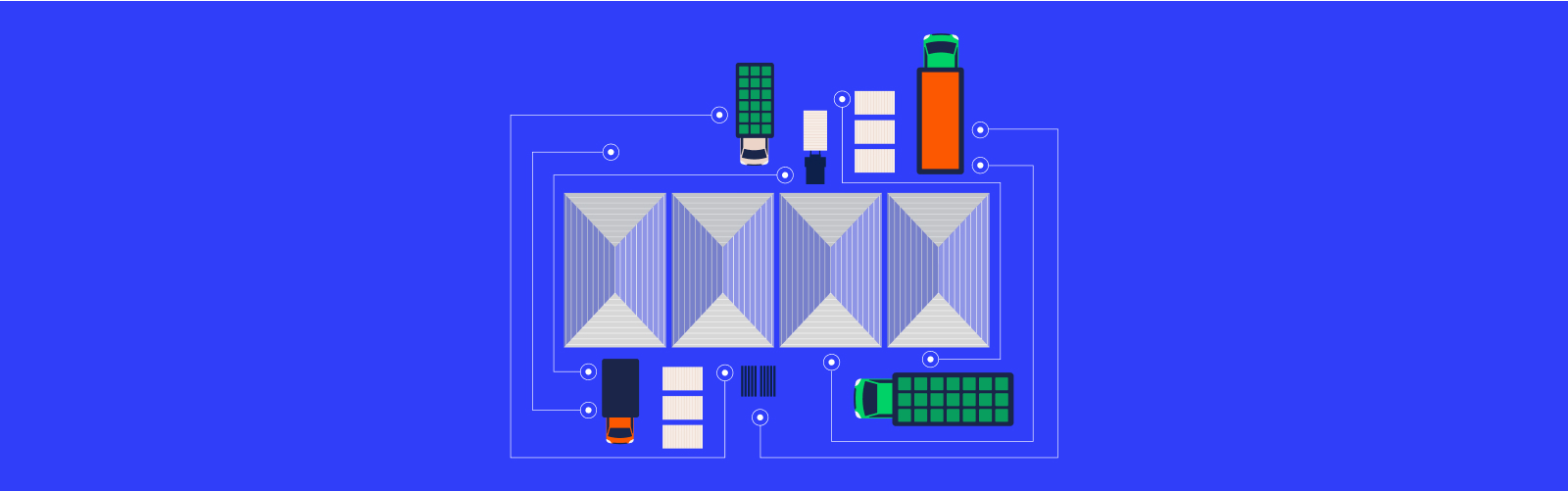

Whether it’s ship-from-store, store pickup, or simply checking what’s in stock, omnichannel fulfillment has become the new norm of retail. Customers want an option as to how they shop, and they want those options to integrate with one another seamlessly.

Of course, customer expectations are one thing; implementing them is something else entirely. Omnichannel retail relies heavily on a robust inventory management system. The more fulfillment channels a brand attempts to manage, the more important it is to have means of inventory optimization. This includes balancing inventory between physical stores and online shopping platforms to ensure efficient order fulfillment.

This article will explore how inventory management and omnichannel retail strategies are intertwined and how having the right inventory optimization systems in place can help an organization streamline its operations, control costs, and deliver a customer experience that goes above and beyond expectations.

The Role of Inventory Management in Omnichannel Retailing

Inventory management is the backbone of a successful omnichannel retail strategy. It enables retailers to manage their stock levels, track inventory movements, and fulfill orders efficiently across all channels. Effective inventory management ensures that retailers can meet customer demand, reduce excess inventory, and minimize stockouts.

By optimizing their supply chain, retailers can streamline logistics and improve overall operational efficiency. This not only helps in maintaining the right inventory levels but also enhances the ability to respond quickly to changes in customer demand and preferences, ensuring a higher level of customer satisfaction.

How Inventory Management Makes Omnichannel Fulfillment Work

Retail fulfillment isn’t always the most straightforward process. Geopolitical tensions, rising transportation costs, natural disasters, and other black swan events all put pressure on the global supply chain, which is in a precarious balance even at the best of times.

That’s why managing a company’s inventory is integral to efficient omnichannel fulfillment and execution. The more fulfillment channels a brand is attempting to operate, the more delicate the balance becomes. Below are five of the biggest challenges of omnichannel retail and how they can be addressed with inventory optimization.

Fragmented Inventory Data Across Channels

Fragmented inventory data is much like operational quicksand. It snares efficiency, bogs down operations, and puts a drain on an organization’s resources. The problem with omnichannel retail is that it introduces more moving parts to an already complicated system, meaning it is decidedly more likely to have fragmented data. Many retailers will attempt to manage multiple data sets for managing in-store stock, e-commerce stock, and store pickup inventories. Because these data sets are siloed, there are often discrepancies in inventory levels, resulting in missed sales and poor customer experiences.

For example, the system shows that there is an item in stock when the customer places the order for store pickup. After arriving at the store, they’re informed the item is actually out-of-stock, resulting in a wasted trip and an unhappy customer. Accurate inventory data leads to higher customer satisfaction by ensuring product availability.

Solution: Data integration is the key. Retailers need an inventory management system that provides a single source of information across all channels. A cloud-based inventory system that can monitor and report on all fulfillment channels, warehouses, and in-store inventory levels consolidates all of the data, resulting in more accurate inventory levels and reporting.

Moreover, the combination of inventory optimization and shipping from multiple warehouses can drastically increase efficiency, especially during peak season.

Stockouts and Overstocking

Stockouts and overstocking are common problems that come with inefficient inventory management systems. Stockouts occur when demand exceeds supply and brands simply don’t have the inventory in place to meet sales needs, resulting in missed opportunities and profits. The flip side of the coin is overstocking, which often occurs when a company ends up overcorrecting an insufficient inventory. Overstocking can end up tying up capital and resulting in markdowns, waste, and lost profits.

Solution: Inventory optimization tools help manage inventory by tracking current inventory levels, besides providing accurate forecasting and insights. Companies need to be able to leverage historical sales data and customer preference, applying that to current customer behavior patterns and seasonal trends to adjust their inventory levels appropriately. This not only reduces the risk of too little or too much inventory, but also allows retailers to shift inventory between locations as needed, ensuring better fulfillment for customers.

In addition, Just-In-Time (JIT) inventory management can help retailers achieve a more precise balance by stocking inventory only as needed, based on real-time demand signals. This approach minimizes excess stock while ensuring timely replenishment, significantly reducing carrying costs and waste. When paired with robust forecasting tools, JIT allows retailers to dynamically allocate inventory between locations, meeting customer demand efficiently while avoiding overstock and stockout scenarios.

By combining predictive analytics, JIT inventory practices, and flexible inventory redistribution, retailers can ensure smoother omnichannel fulfillment and enhanced customer satisfaction.

Supply Chain Disruptions

As mentioned above, supply chain disruptions are still incredibly prevalent, especially due to extreme weather events such as storms and droughts. Regardless of the cause, supply chain disruptions can wreak havoc on omnichannel fulfillment and inventory management. Given the fact that supply chains generally span the globe, the likelihood of experiencing disruption increases with the number of fulfillment channels a company is attempting to manage.

Solution: As disruptions are inevitable and typically unavoidable, it comes down to building flexible and agile supply chains. Eliminating reliance on a single supplier and using multiple sources is a proven strategy to ease supply chain disruptions. Additionally, inventory management systems that provide tracking insights in real time allow retailers to quickly assess stock availability and adjust fulfillment as necessary. Furthermore, having a system that provides customers with quick and easy notifications in the event of a delay goes a long way toward improving the customer experience.

Order Fulfillment Accuracy

Managing multiple fulfillment channels means there are decidedly more opportunities for order accuracy to be impacted. Inaccurate orders create a ripple effect, affecting inventory levels, shipping costs, shipping times, and customer satisfaction. Mis-picks, damaged goods, or wrong items being shipped to customers are all potential risks of poor fulfillment accuracy, all of which can damage a company’s reputation.

Solution: In addition to utilizing an inventory management system, an effective strategy to improve order fulfillment accuracy is utilizing automated warehouse systems. Automated warehouse systems, such as systems that automate order picking and packing or generating shipping labels, remove opportunities for human error, which significantly impacts accuracy ratings.

Managing Returns Across Channels

Returns are inevitable, especially when it comes to omnichannel retail. Unfortunately, return logistics are often more complicated than standard logistics, as most companies are typically only optimized to ship to a customer and not the other way around. Poor return logistics end up costing companies a significant amount of money and time, in addition to negatively affecting inventory management.

Solution: Utilize a returns management system. In reality, even companies that aren’t engaging in omnichannel retail should be using a returns management system. Here again, it’s less so about the logistics (although that is important) and more about the customer experience. A cumbersome or inefficient returns process is incredibly likely to damage a customer’s trust and satisfaction. Providing a quick and easy process is important as returns tend to frustrate customers. For example, providing a return option that can be integrated with the store pickup process provides customers with a familiar and easy-to-use way to return items.

Additionally, a proper inventory management system is important for keeping track of returns and determining which items are in saleable condition versus those that need to be disposed of or sold through different means.

Inventory Management and Omnichannel Retail: Two Parts of a Winning Strategy

Managing multiple fulfillment channels is a lot like trying to juggle in the dark. With so many moving parts, it’s all too easy for mistakes to happen. Unfortunately, a missed catch here often means the loss of a customer and a damaged reputation. To that end, inventory management is an essential part of the omnichannel retail strategy. By tightening control on inventory, retailers can improve their operations, control costs, and better manage the overall retail experience for their customers.

Click here to get a demo of how Metapack can help you deliver an exceptional omnichannel experience to your customers.